Experts mull ways to tackle substandard materials menace

The Government of Kenya is talking tough amid the growing cases of counterfeits and substandard building products continuing to flood the market thus costing the taxman heavily.

Through various agencies, such as the Kenya Bureau of Standards (KEBS), National Construction Authority (NCA) and Anti-Counterfeit Authority (ACA), the Government is vowing to crack down heavily on sector destroyers even as manufacturers in the space bitterly endure losses of revenue and market share due to unfair competition.

Industry players during a recent roundtable meeting, while advancing other causes of building collapse, such as quackery, unethical practices by professionals and poor regulation and monitoring of the sector by government, they expressed concern that substandard materials play a big role.

State Department of Industry-Ministry of Trade and Industry Principal Secretary Juma Mukhwana acknowledged the different levels of challenges in managing the sector, but called on all players to have a common goal and understanding of the root causes, so as to identify solutions.

“Our role as Government is to encourage and enhance manufacturing as a key enabler to the Vision 2030 and also as part of the government’s agenda. At the same time, we want our manufacturers to produce what is quality and, therefore, of quality standard. It is within our mandate to protect our consumers and thus can be achieved if we all played our roles as players,” he said at Mabati Rolling Millers (MRM) plant in Athi River, Machakos County, during the launch of the MRM 100 per cent Guarantee Warranty of its steel products in the market.

Incremental taxes

The meeting also saw the manufacturing community call for more stringent measures of illicit traders in the space who were offering substandard products at a lower fee and taking advantage of the lack of awareness among end-users.

“The main problem I found with this industry is confusion in the sense that the big boys want to do small things while the small boys are overambitious. We need to integrate all ideas better. In the sheets sector, for instance, we have a capacity of 12 million tonnes yet our need is only nine million, and yet we still import and then complain. We have a situation where there is hoarding by manufacturers, but I think the answer to this issue is for our industries to begin producing for even the smaller players. In the future, we might also be thinking about doing incremental taxes on products manufactured out of Kenya, so as to protect the players here,” he said.

Safal Group CEO Anders Lindgren pointed out to the overall picture of Kenya’s Economy that has encouraged cheats and misfits to take over the building sector thus leaving a trail of disaster in their wake.

“Sadly, this is a generic Kenyan problem and we could point out to the state of the economy and high cost of living where lots of Kenyans will go for cheap at the expense of any consequences. At the same time, taxes are a huge problem, because they cripple the state of production for most industries in the building sector. However for me, consumer awareness is what is mostly lacking and where a lot of us need to invest. There are a lot of people who do not know the difference between quality iron roofing sheet to what is not, and this is what makes us lose our market share and customers ultimately get a raw deal. The problem with roofing products is also that with an untrained eye, it is hard for the ordinary buyer to know what is quality and what is sub-standard,” stated Lindgren who revealed that the government had lost in excess of Sh5 billion (US$40 million) in import duty due to poor quality products and about 30 to 40 per cent volume in sales were affected for MRM as a brand due to low tonnage.

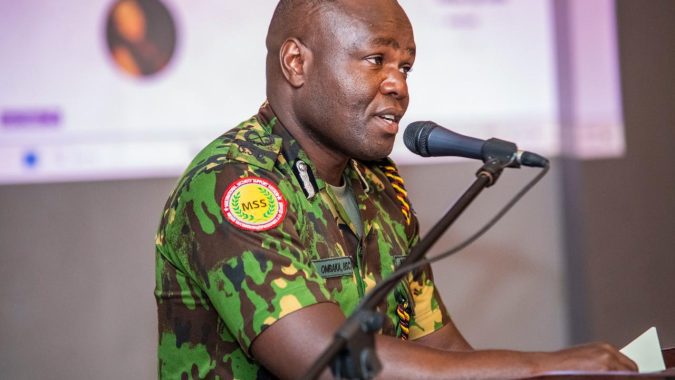

KEBS Managing Director Lt.Col (Rtd) Bernard Njiraini while admitting lapses in the entire value chain of the construction and building sector, told of KEBS renewed effort in curbing short cuts.

“We play, as an agency, an extremely important role of checking compliance in products that are ultimately used to build homes or offices. We basically govern standards and ensure products are manufactured. We have conducted sensitisation on this matter before and we continue to make consumers aware, because at the end of the day, it is their planned investment for ages. We have gone ahead with the times and our scrutiny and checks are up a notch, so that the war against substandard goods in the market is won,” he said.

Business competency

He went on: “ Companies, such as MRM have had engagements with us for a long time since their products keep changing due to technological advancements, which is crucial. We have been able to establish quality control measures to protect consumers in this country, so that they can only deal with the best there is even if it means spending a little bit more. Enhancing business competency in this area is important so that developers can only get to deal with standard products. It is unfortunate that despite falling under the Africa Continental Free Trade Agreement (ACFTA), we still get complaints from neighbouring countries complaining of substandard products that are from here or pass through our borders yet we are supposed to lead by example.”

Mabati Rolling Mills (MRM) CEO Manish Mehra on his part told the attendees that the firm through their new warranty deal was convinced that order would return. “Our duty is to the consumer and so it is in our interest to protect that segment. We want to pay back the trust and indeed now start a journey of renewed engagement with our Customers. At MRM, we do not get too many opportunities to influence consumers and so we have to be creative. The warranty ensures that all our products will be branded and quality compliant as per standardisation rules. The journey ahead will be tough because we are dealing with customers whose biggest weapon is choice, which is ultimately decided by pricing. So for us it is about balance and finding new areas of development to attract even a bigger market space,” he said.

Kenya Association of Manufacturers (KAM) CEO Anthony Mwangi told of the importance of elevating the conversation.

“This conversation cannot be left at policy level, because tough action must be complementary even to the Laws in place. Between 2017 and 2022, the KAM report and Anti-Counterfeit Authority (ACA) baseline survey estimates that the country has lost in the region of Sh2.6 trillion due to substandard products and, therefore, as the manufacturing watchdog body, this has to concern us a great deal.

“Manufacturing contributed 7.2 per cent to the Gross Domestic Product (GDP) and, therefore, with substandard products marooning our country, then it means that what goes to waste is in fact bigger than our country’s GDP, which is serious,” he said in conclusion.