Farmers urged to get technology that’ll increase milk yield, income

Milliam Murigi @millymur1

Use of emerging technologies in dairy farming have helped farmers cut the cost of milk production by about 20 per cent and increase national productivity by 19 per cent over the last five years, a new report has shown.

Dubbed Cost of Milk Production Study Report 2021, the report, which was commissioned by the Kenya Dairy Board to Tegemeo Institute of Agricultural Policy and Development shows that unlike before, more farmers have now adopted labour-saving technologies, such as padlocking, use of chaff cutters, milking machines, hay balers, and feed preservation in form of hay and silage, a step that has helped reduce the cost of producing milk.

According to the report, gross revenue from milk has also improved by three per cent over the last half a decade, because of the improvement in producer prices for milk.

“On average national productivity of milk per cow increased by 19 per cent from 6.4 litres in 2014 to 7.9 litres in 2019,” reads the report.

The annual production of milk in 2019 was estimated at 5.5 billion litres of milk, a growth of 12 per cent from the 4.9 billion litres produced in 2018.

On average, a dairy farmer in 2019 earned milk profits of Sh12.20 per litre compared to Sh4.20 in 2014.

Profitability varied with the production system, highest for semi-zero grazers at Sh14.27 per litre, and lowest for zero grazers at Sh8.57 per litre.

“The average profitability per litre of milk produced rose to an average of Sh16.20 in 2019, when other farm revenues, such as the sale of livestock and manure were considered.

This should excite and motivate farmers and potential investors to increase investment in milk production,” reads the report.

However, despite the good news, the report reveals that a lot more still needs to be done to make the industry more competitive regionally and globally.

The reason being the cost of milk production remains high at an average total cost of Sh23.30 per litre for zero grazers, Sh23 for semi-zero grazers, and Sh17.24 for open grazers.

It shows that the largest cost components of producing milk are feeding and labour.

For example, under zero-grazing, the cost of feed concentrates to total variable direct costs was 40 per cent, followed by purchased fodder and hired labour at 22 per cent each.

These highlights the key interventions needed to lower the costs of producing milk.

“Across the production systems, feed concentrates, hired labour, purchased fodder, health and breeding accounted for the largest cost shares.

A reduction in the cost of all these components will result in a reduction of total variable direct costs,” reads the report.

Since a large proportion of the labour time is spent on feeding, particularly harvesting and chopping nappier grass, the report recommends that farmers must invest in labour saving technologies.

“Labour is a large component of total costs across all milk production systems and use of labour-saving technologies can reduce its cost.

Some of these technologies have managed to reduce labour requirement in dairy production by more than 50 per cent,” it reads.

Apart from that, the country has also been experiencing declining herd sizes per farm.

The average herd size per farm declined from nine animals in 2014 to six animals in 2019, although the number of milking cows remained relatively stable.

This decline undermines our capacity as a country to be self-sufficient in milk and milk products.

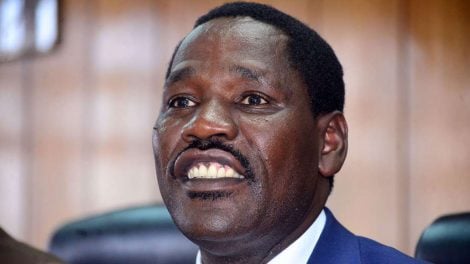

Speaking during the release of the report, Agriculture Cabinet Secretary Peter Munya said that Kenyans must manage the costs of feeding and labour in their milk production systems if they are to improve productivity and manage costs.

He revealed that the government is exploring public-private partnerships for large-scale production, conservation, and distribution of fodder and pastures.

This will reduce cost and improve the accessibility of fodder and feed in the country.

“Labour saving technologies are required by dairy farmers to manage operational costs.

The Government is promoting the uptake of these technologies by dairy farmers through capacity building and provision of credit facilities by Agricultural Finance Corporation, Banks, and other financial service providers,” said Munya, urging more farmers to embrace dairy farming, because with a growing population and increasing per capita consumption of milk and milk products, Kenya needs to sustainably improve the production of milk to serve the domestic and export markets.

“The Kenyan dairy industry must rise and face the threats posed by increasing globalisation and regionalisation of markets.

We must clearly identify and provide solutions to the challenges affecting productivity and efficiency in the dairy value chain,” he said.

And since the report indicated high operational costs and inefficiencies under small scale milk production systems, Munya urged farmers to gradually transform to more intensive medium to large scale milk production systems so as to improve efficiency in milk production.

According to him, this is possible through private, public, and communal investments in milk production.