Kisumu youths strike gold in modern fingerlings hatchery

Fish catch from natural water bodies in Nyanza region has continued to dwindle over the years leading to a drastic drop in overall supply.

It is against this backdrop that a group of youths in the region have initiated a process of boosting farm fish yields to balance the deficit.

The group, Victoria Aquaculture Youth Group is promoting aquaculture through supporting related value chain activities.

Comprising of 10 members, the multisectoral team of unemployed young graduates from different universities, with various professional backgrounds ranging from aquaculture to engineering, has taken the lead in disseminating aquaculture techniques through a new model of fingerlings production.

Three members have background skills in aquaculture, two electrical engineers, one physicist, one mechanical engineer and a surveyor.

“The basic resource we had at that time of job seeking was our skills and knowledge in the various spheres.

We didn’t have money to start any income generating activity,” recalls Vincent Oduor, the group’s chairman.

They registered their group in November 2019 as a self-help group before rolling up their sleeves for any job opportunities that would come their way.

They began farming activities in the informal settlement of Nyalenda in Kisumu town where they run fingerlings hatchery facility, which was set up by Kisumu county government as a pilot project.

“The early founders of the group were specialised in aquaculture, so we discovered it as our familiar territory,” Oduor says.

The youths design and construct hatcheries for fish farmers by order by replicating the pilot model in Kisumu.

Already, they have established replica hatcheries under the technology for fish farmers in Siaya, Kakamega and Nakuru counties.

The cost of installing the structures depends on the downscaled design and the farmer’s preference. It is also determined by the size of production target that a farmer needs.

They also do general consultancy aquaculture services for farmers with a view of equipping them with modern fish farming know-how.

The hatchery process starts with female fish brooding stock identification, which is followed by crossing them with males in a ratio of three to one, between seven and 10 days.

The eggs are then collected, cleaned and transferred into incubators, then into McDonald hatching jars and eventually in the incubation section, which has running clean water that keeps the eggs in gentle motion throughout day and night for about three to four days when they all hatch.

The hatchlings (the larvae emerging from fertilised eggs) are then transferred into the hatching tray.

The tiny fish then grow into fries (young fish about one to two centimetres in length) and are led into the sex reversal tanks.

In the reversal segment, the fries are regularly fed and treated with sex reversal hormones for about 21 days before they develop into fingerlings.

Standard size fingerlings take about three to four weeks and are approximately three to four centimetres in length.

During this period the fries are capable of feeding themselves. They are fed exclusively on hormone less feeds to get a higher percentage of sex reversal.

The exercise, he says, accelerates fish growth, noting that commercial farmers prefer fish that grows fast and uniformly. These qualities are possessed by the male fish.

“It is easier for the commercial farmers to manage the male sex fingerlings because of their unique genetic characteristics. It can help them plan for the market as well,” he says.

Gilbert Omondi, the youth group treasurer says the venture is a source of inspiration to fish farmers locally as it is contributing immensely to modern aquaculture practices.

On average, he says the group earns between Sh10,000 and Sh30,000 monthly depending on the jobs available.

He urges youths to take up opportunities presented in fish farming in order to earn themselves direct jobs.

“Aquaculture is today becoming one of the leading contributors to the growth of the economy, let’s take a chance and give it our best because it pays just like any other job,” explains Omondi.

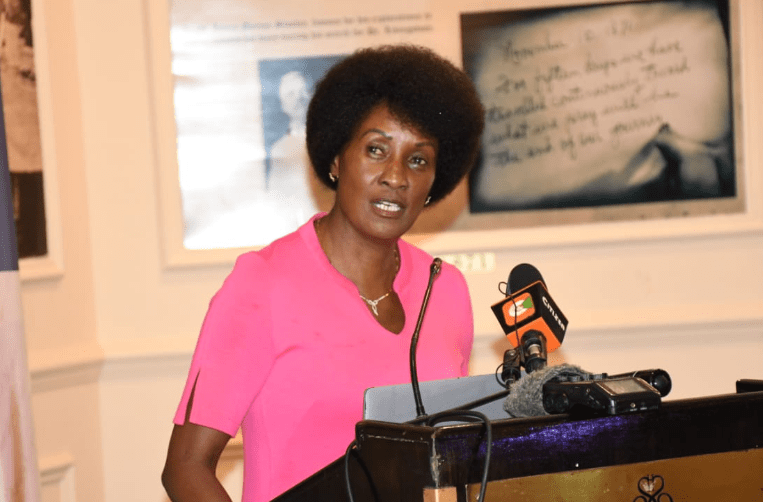

Kisumu county director of fisheries Susan Adhiambo says young people are attached to the facility to get hands-on experience and disseminate the skills to other farmers.

She notes that adoption of the new model is primed to boost fish production locally, saying that currently, the facility is able to produce between 20,000 and 25,000 fingerlings per month.

Adhiambo says the new model is advantageous for reasons, such as taking little space, easy to manage unlike the natural earthen ponds, climate smart, offers high production rates for fingerlings and is cost effective to run.

The hatchery uses waste water drawn from sewerage ponds, which is recycled into the system for subsequent productions.

Adhiambo points out that the objective was to demonstrate that waste water can be recycled and used for fish farming.

The fish hatchery facility also acts as a research and innovation centre, and as a learning centre where individual farmers and students visit on matters fish farming.

The director points at lack of quality fingerlings, high cost of fish feeds, marketing, poor attitude by residents towards fish farming, inadequate extension officers and poor pond management practices as major challenges facing fish farming in the county.

The fingerlings hatchery is a pilot project jointly initiated by the European Union and Kisumu county government and seeks to improve farm fish production.