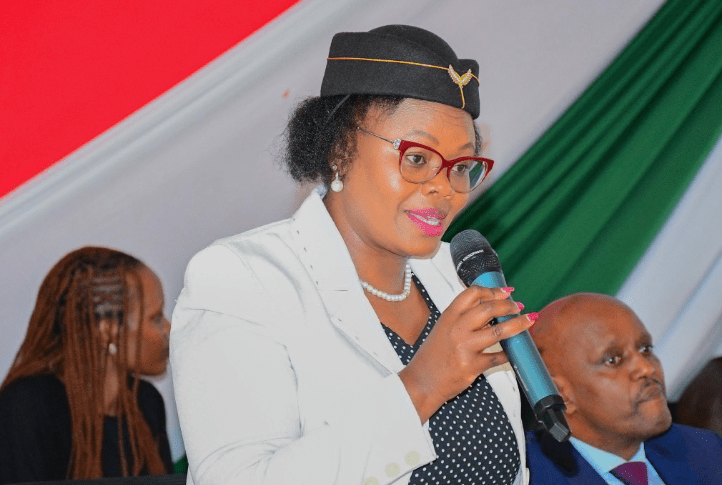

Love for a skill saw Joan create business, earn a living

On October 4, 2019, Joan Odhiambo, now Bwire, walked down the aisle to the love of her life donned in a gown she had crotched herself, and surrounded by bridesmaids in designs she created.

It was the culmination of six months of hard work and dedication. All she wanted was unique nuptials, where she would wear her brand- something that was heartfelt with a story behind its creation.

“I wish you knew the energy and commitment I had to make this work. It wasn’t easy though, because I would undo it a couple times to fit to my liking.

I didn’t have a written pattern to copy from: it was all from my mind, just mixing everything up to achieve what I wanted,” she narrates.

Her brand, dubbed Joheartyarns, designs and makes handmade crochet swimwear, beachwear and bridal gowns.

Having been in business as a crotchet designer for five years, her spectacular gown was something she was confident of finishing.

“While crafting my gown we made a deal with my fiancée that he wouldn’t see it till the wedding day. It was emotional when he saw me walk down the aisle in the gown.

I remember his words, ‘ I knew you are good at this, but I didn’t know you would pull such a masterpiece’,” says the crotchet designer enthusiast.

At the age of 10, Joan learnt crocheting from her mother. By definition, crotcheting is the process where textiles are created by employing a crochet hook to interlock loops of yarn, strands or thread.

Crotchet means a small hook in French and the hooks can be made from materials such as wood, bamboo, metal or even plastic.

As she describes, at first, it was all for fun, but she lost interest along the way until 2015 during her final year in campus when she became passionate about it.

Customised pieces

“My friends encouraged me to open an Instagram account to showcase the stuff I had made and to my surprise, people warmed up to them. I remember starting out making house slippers, baby dresses and scarfs,” she says.

She literally made everything out of yarns before she decided to specialise on swimwear. She discovered everyone was excited about it just as she was when they requested for customised pieces.

The International Relations and Diplomacy graduate creates all her designs purely by hand. For her, no machine can duplicate hand crochet work.

She loves to research on latest designs online, especially on Pinterest, which inspires her to know the latest trends. She is also inspired by her clients’ tastes and designs.

Like any other business, crocheting is labour intensive and time consuming, which hinders quick production process.

Swimwear takes around one to three days depending on design and size. A simple design can take a day and the most complicated ones takes up to three days.

Her work, too, is labour intensive and sometimes, finding time to train workers to run her company is difficult.

“It’s all about commitment. When you are self-employed, the feeling of being your own boss can sometimes make you a bit lazy.

I work eight hours a day, and most orders have a timeframe, so I plan my time well to deliver in time.

I also work with three ladies who are helping me out with the orders so there’s that aspect of duty delegation,” adds Joan.

Wrong perceptions

Another challenge is getting readily available quality yarns in the local market. There are different types including cotton, wool, cashmere, and acrylic and each has its own unique kind of thickness.

However, she is sometimes forced to import yarns, which is quite costly and she has to make sure the yarns she selects are quality otherwise, it will affect her designs.

“For gowns, I prefer using 100 per cent mercerised cotton yarn, thin in weight. It’s breathable, feels good on the skin and the quality withstands tear and wear.

Unfortunately, Kenya only manufacturers’ acrylic yarn, this delays effective production if a client prefers cotton,” explains Joan.

Mercerisation is a textile finishing process for fabric and yarn especially cotton, flax and hemp to improve dye uptake and reduce fabric shrinkage.

The gowns depend on design and size as well. For instance, the mermaid dress she wore on her big day would cost Sh50,000. However, even with such quality products, Joan observes that some clients don’t appreciate handmade products and complain that her work is too pricey.

Joan wants her company to run for a long time and offer employment to many youth.

“I’m trying to build a brand and a big company. Creating job opportunities and impacting life is part of my agenda. You know, something I can leave for my children and many more generation to come,” she concludes.